Nickel-based brazing filler metal is a brazing material composed of nickel as the base matrix, combined with low-melting elements such as boron, silicon, and phosphorus, as well as strengthening elements like chromium, cobalt, molybdenum, tungsten, and iron.

BNi-2 is one of the most widely used nickel-based brazing alloys, characterized by a low melting temperature, good wettability, and fluidity. During the brazing process, the base material grains do not grow, which helps prevent deterioration of component performance.

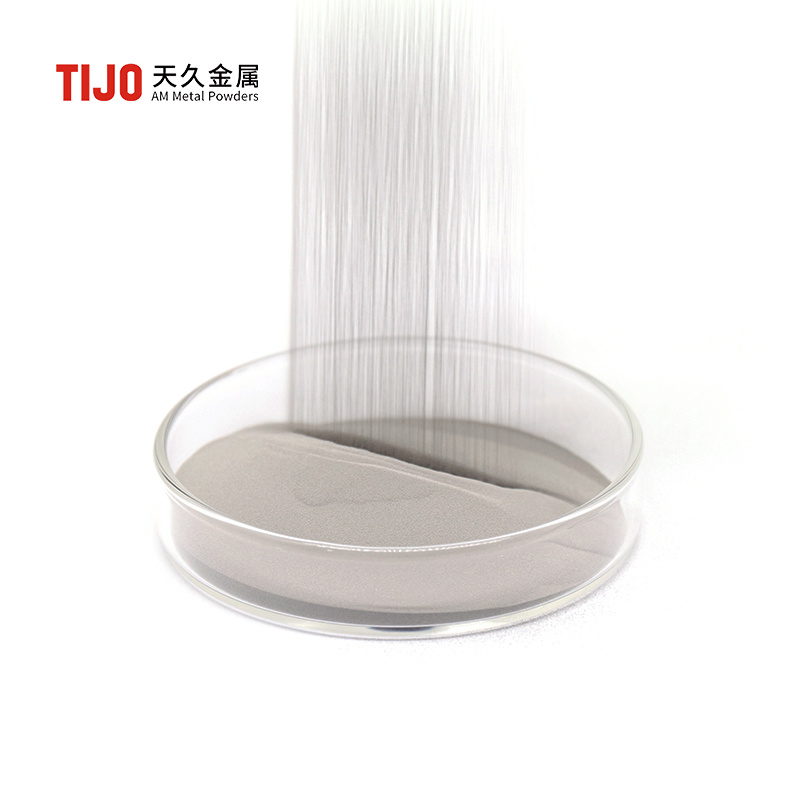

1. High-Temperature and Corrosion Resistance Temperature range: -200°C to 1000°C, oxidation and sulfidation corrosion resistance. Resistant to seawater, chlorides, and acidic media corrosion, suitable for marine and chemical environments. 2. Excellent Processability High sphericity (≥98%), low oxygen content (≤0.1%), good fluidity, reducing 3D printing defects. Strong bonding strength with the substrate, supporting the formation of high-precision complex structures. 3. High Strength and Toughness Room temperature tensile strength ≥900 MPa, maintaining excellent mechanical properties at high temperatures.

1. High-Temperature Performance Applicable temperature range: -250°C to 700°C, resistant to high-temperature oxidation, creep, and sulfide corrosion. Strength is significantly improved after age hardening (room temperature tensile strength ≥ 1300 MPa). 2. Corrosion Resistance Resistant to acids, alkalis, chlorides, and seawater corrosion, suitable for chemical, marine, and nuclear industries. 3. Process Compatibility High sphericity (≥97%), low oxygen content (≤0.1%), excellent fluidity, compatible with additive manufacturing processes such as SLM (Selective Laser Melting) and EBM (Electron Beam Melting). No tendency for cracking after welding, supports the precision forming of complex structures.

High purity, high hardness, wear resistance and corrosion resistance, low friction coefficient, excellent self-melting, wettability and spray welding, high sphericity, low oxygen, smooth surface, uniform particle size distribution, excellent flow properti

Strong corrosion resistance (resistance to oxidizing solutions containing chloride ions), properties of excellent high temperature performance, high strength, good oxidation resistance and mechanical performance

Electrolytic refining, high purity, excellent electrical conductivity, corrosion resistance and figurability

The carbon and boron in BNi-1 brazing filler metal can diffuse into the base material during the brazing process, thereby increasing the remelting temperature of the brazed joint. This filler metal has a high chromium content, so the brazed joint exhibits good high-temperature performance and is suitable for components subjected to high stress at elevated temperatures.

BNi-5 brazing filler metal does not contain boron, significantly reducing its effect compared to the base material. It is suitable for brazing thin parts. This filler metal has a high melting temperature and brazing temperature. Due to its high chromium content, the joint's high-temperature strength and oxidation resistance are comparable to BNi-1.

BNi-7 brazing filler metal is a nickel-based eutectic brazing alloy with excellent fluidity, capable of flowing into tightly contacted joints. The filler metal has minimal corrosive effect on the base material and is mainly used for brazing thin stainless steel parts. Since it does not contain boron, it is especially suitable for the nuclear field.