Soft magnetic powder supplier

Expert in High-Performance Soft Magnetic Material Solutions

Changsha Tianjiu Metal Materials Co., Ltd. focuses on the research and development and production of soft magnetic powder20year, providing core raw materials for soft magnetic materials with high permeability, low loss, and strong stability, empowering innovation and upgrading in the fields of electronics, power, new energy, and automotive electronics.

What are soft magnetic materials?

Soft magnetic materials are magnetic functional materials with low coercivity and high permeability. They can quickly respond to changes in external magnetic fields and efficiently complete the conversion of electrical energy to magnetic energy, widely used in the manufacture of electromagnetic components.

Core Characteristics:

- High Permeability: Fast magnetization, improved device efficiency

- Low Loss: Reduced eddy current and hysteresis loss, energy saving and consumption reduction

- Wide Frequency Adaptability: CoverskHztoMHzhigh-frequency scenarios

- Temperature Stability:-50℃~200℃ stable operation

Common Classifications:

- Metallic soft magnetic materials (iron silicon, iron nickel, iron-based amorphous)

- Ferrite soft magnetic materials (manganese zinc, nickel zinc)

- Composite soft magnetic materials (prepared by powder metallurgy)

The Core Role of Soft Magnetic Powder

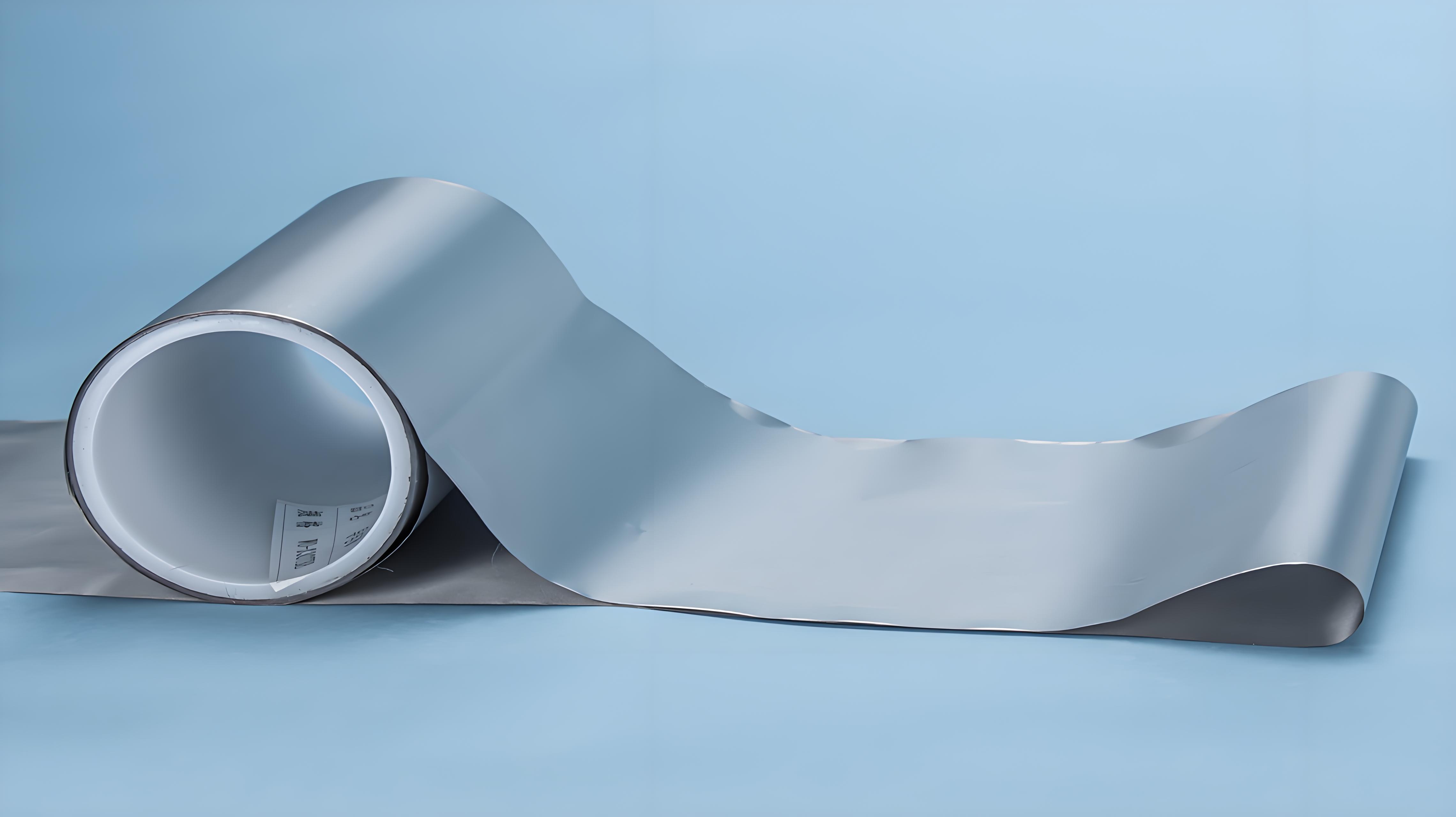

Soft Magnetic Powder—The cornerstone of high-performance soft magnetic materials

Soft magnetic powder is the core raw material for preparing soft magnetic composite materials (SMC). Through insulation coating and precision pressing processes, it can significantly reduce eddy current loss and meet the needs of high-frequency and miniaturized devices.

Tianjiu Soft Magnetic Powder Technology Advantages:

- Precise Particle Size Control:D50 5μm-150μmCustomizable

- High sphericity: Excellent fluidity, uniform pressing density

- Insulation coating technology: Withstand voltage >500V,loss reduction30%

- Various materials: Pure iron powder, iron silicon powder, iron nickel powder, etc.

Seven Application Areas of Soft Magnetic Materials and Powders

① Electronic Power Equipment

- Application scenarios: Inductors, transformers, magnetic amplifiers

- Problem Solving: High frequency, miniaturization,EMIsuppression

② New Energy Field

- Photovoltaic/Wind power: Inverter filter inductors,Boostinductors

- Energy storage systems:BMSElectromagnetic shielding materials

③ Automotive Electronics

- Motor drive modules, on-board chargers (OBC)

- Compliant withAEC-Q200automotive-grade reliability standards

④ Consumer Electronics

- Mobile phone wireless charging coils, laptopEMIsuppression

⑤ Industrial Automation

- Servo motor cores, sensor magnetic shielding

⑥5GCommunication

- Base station toroidal inductors, radio frequency devices

⑦ Medical Equipment

- MRIshielding materials, medical power modules

Why Choose Tianjiu Soft Magnetic Powder?

- Full industry chain capabilities: One-stop service from powder research and development to finished product testing

- Technical Certifications:ISO 9001、IATF 16949System certifications

- Customized services: Optimize particle size according to customer working conditions/Encapsulation process

FAQ:

Q1:What is the difference between soft magnetic powder and ferrite?

A1:Soft magnetic powder achieves higher design freedom through powder metallurgy, resulting in lower high-frequency loss and suitability for complex-shaped devices.

Q2:How to choose the soft magnetic powder particle size?

A2:It needs to be matched according to the working frequency and forming process,100kHzSuggestions below50-150μm,MHzHigh frequency recommendation <20μm

*The above pictures are from Baidu. Please Contact Us if there is any infringement.

Recommend products