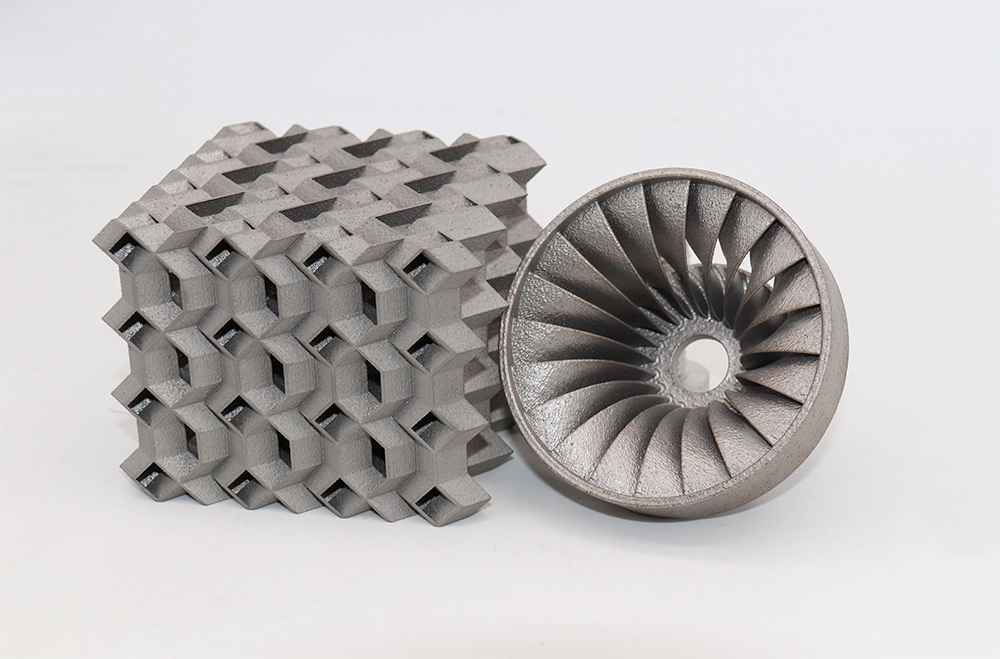

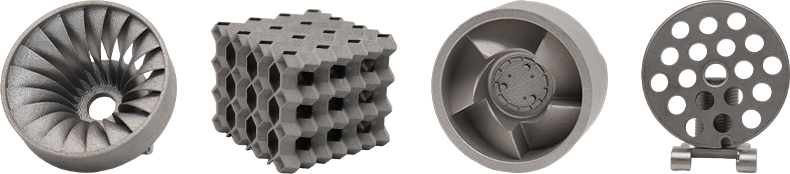

3D Printing

We are a professional metal powder supplier, focusing on providing high-quality metal powders for additive manufacturing and 3D printing.

Get In Touch Today

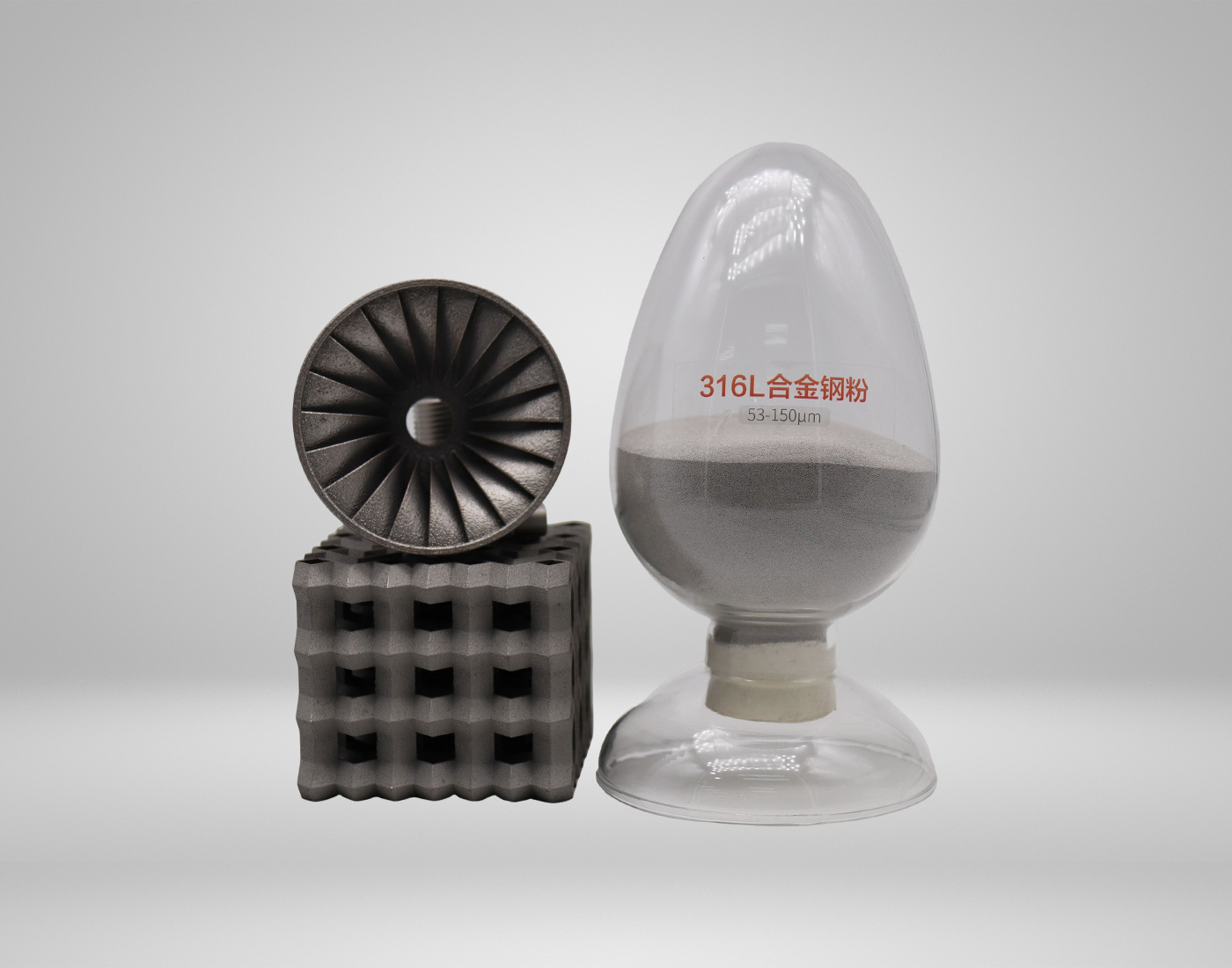

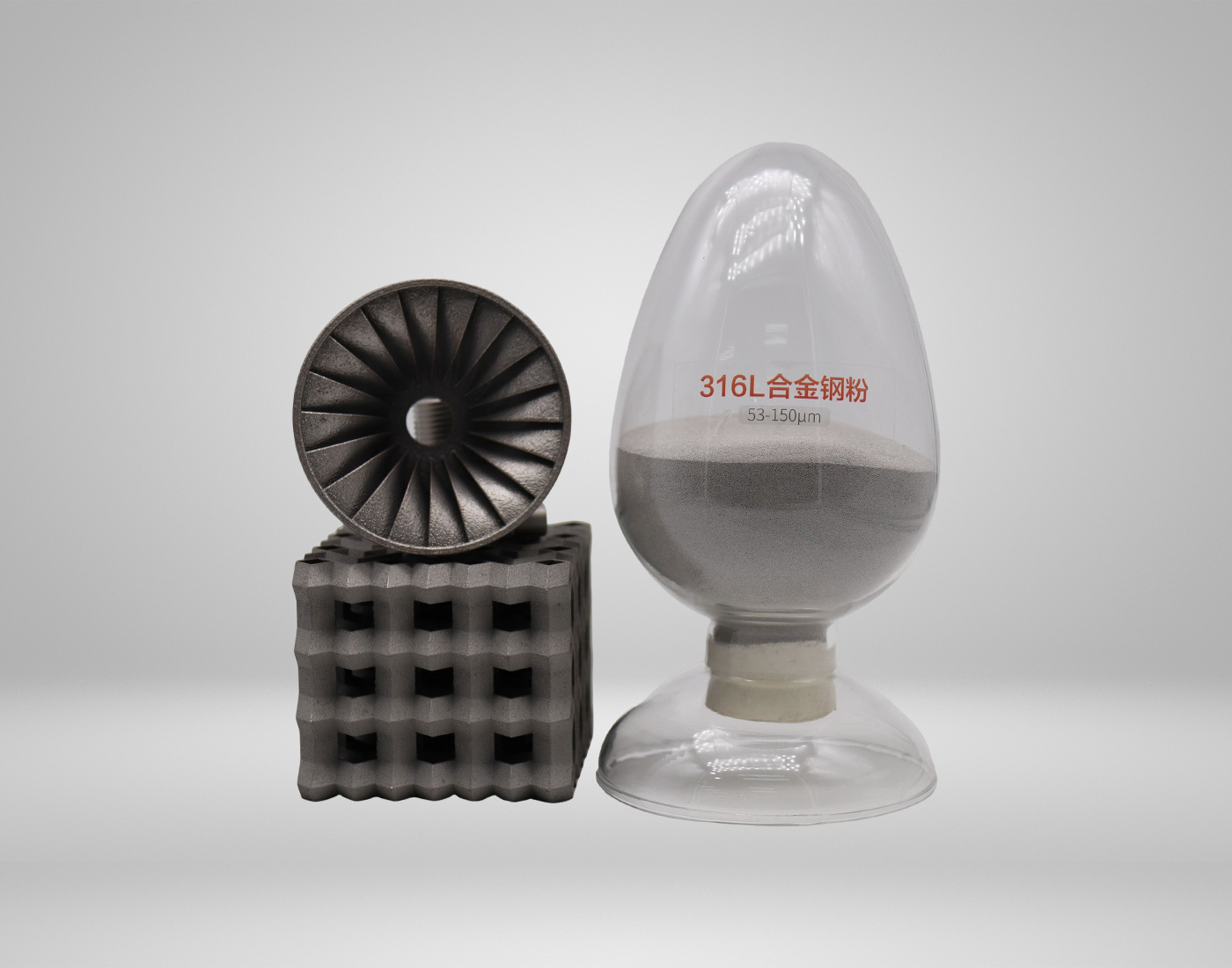

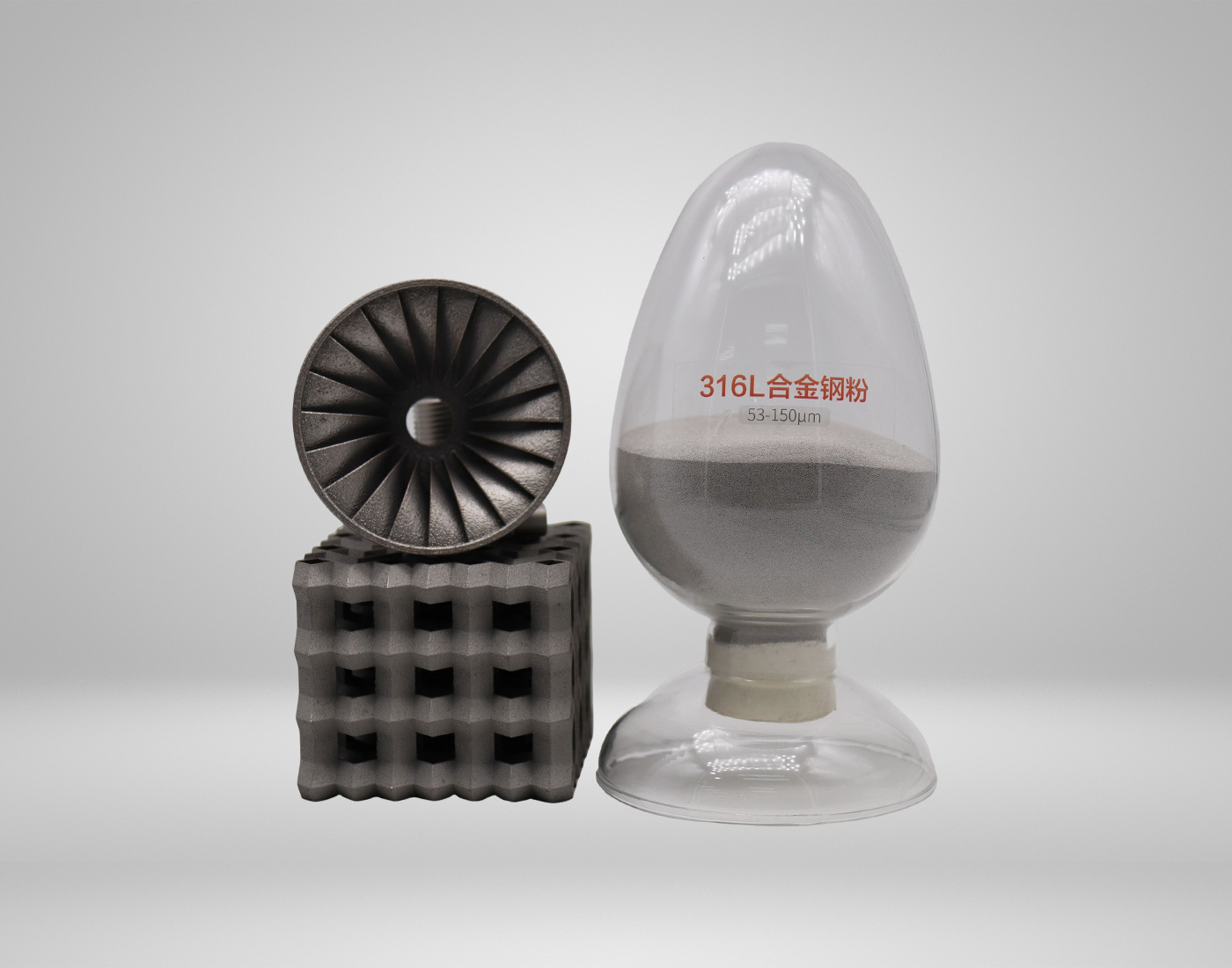

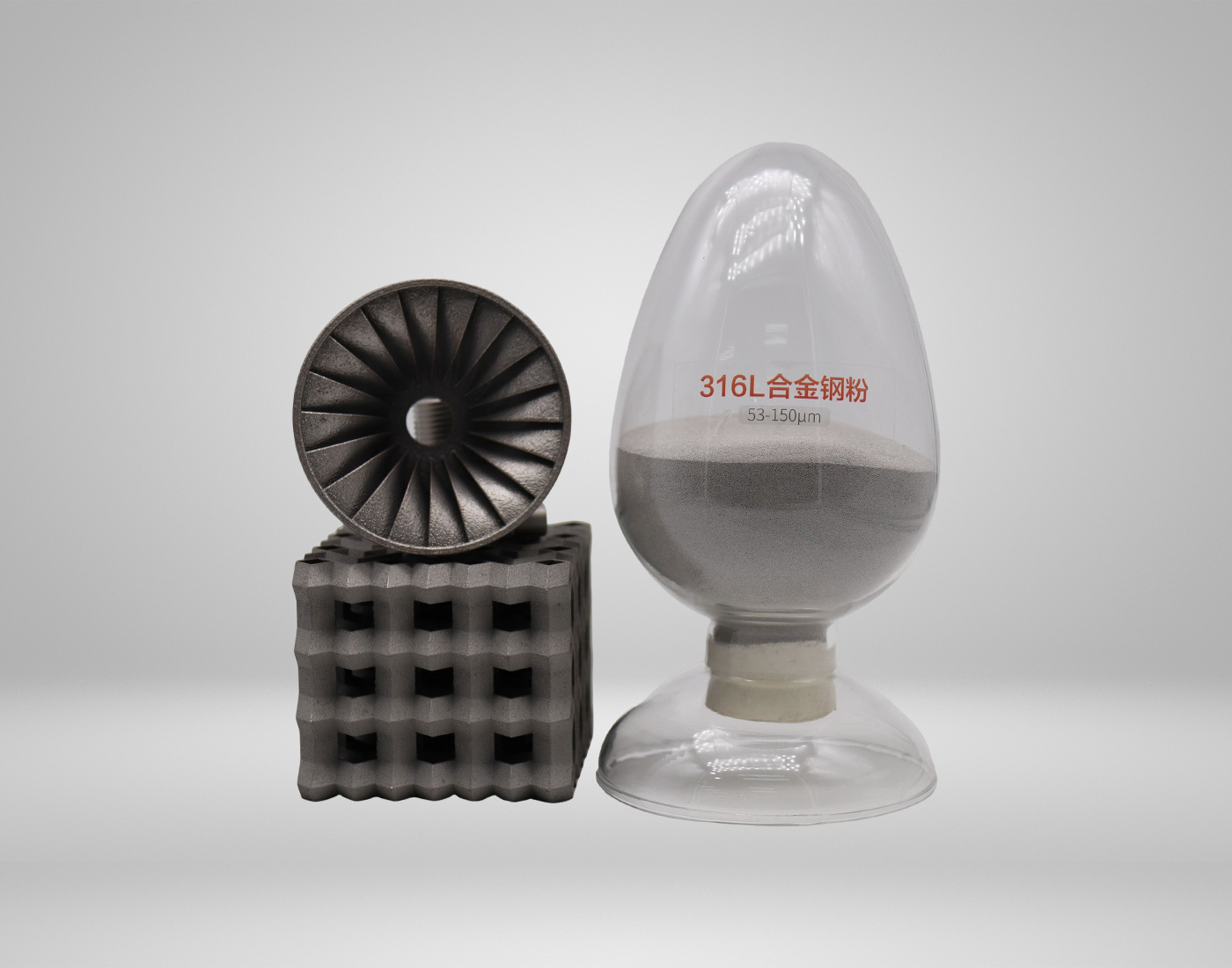

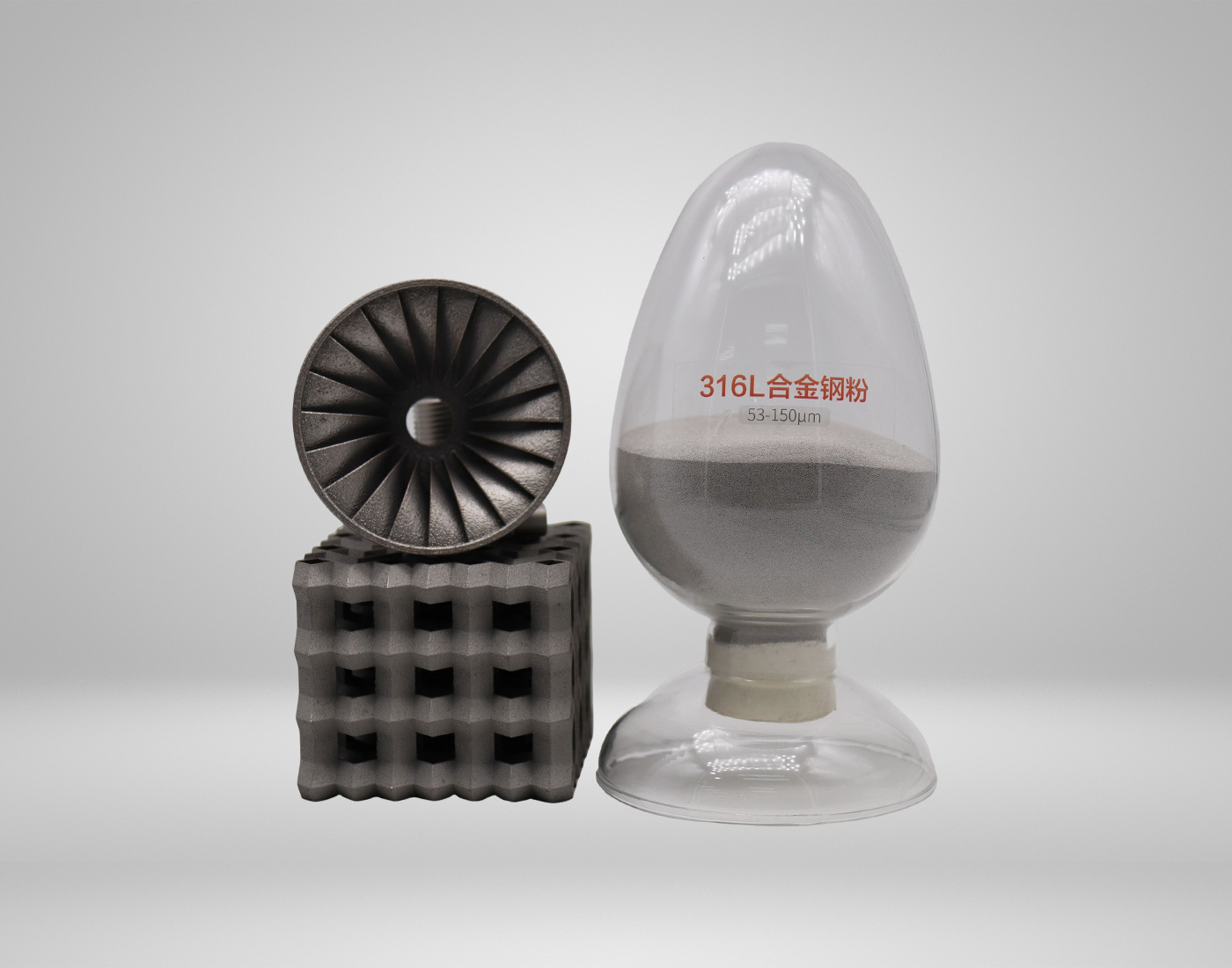

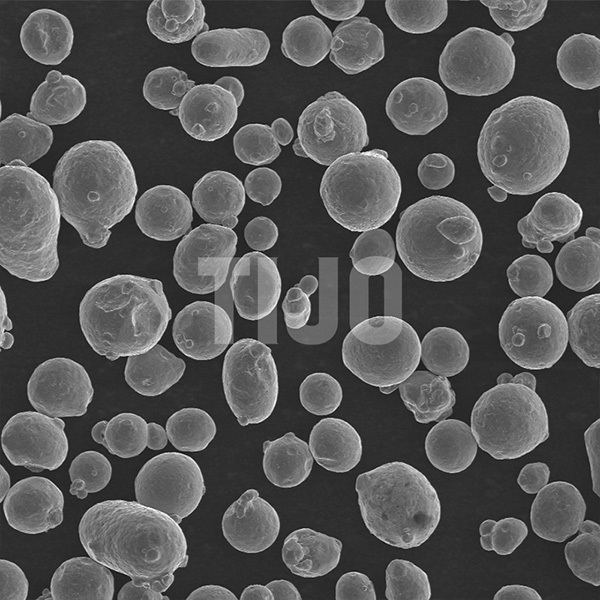

316L (1,4404)

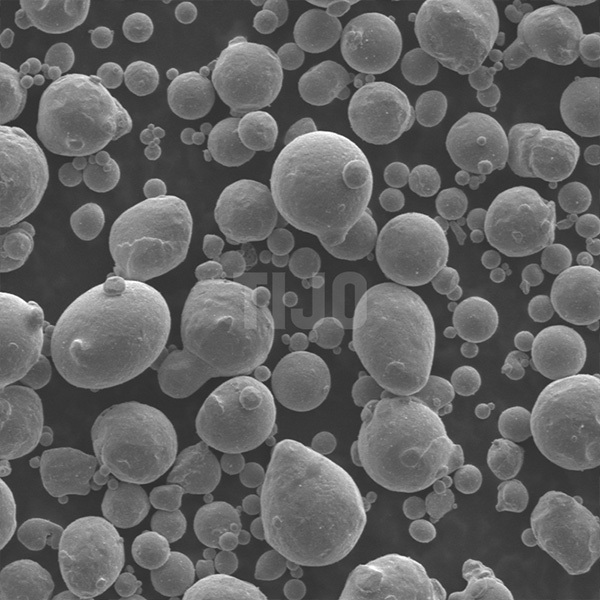

Features:Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity.

Application:

3D Printing

MIM (Metal Injection Molding)

Spraying Welding

PM(Powder Metallurgy)

Multi-hole Material

HIP(Hot Isostatic Pressing)

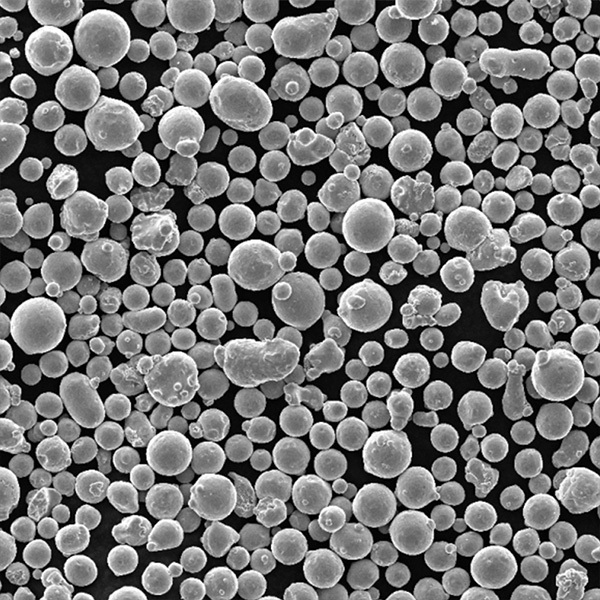

304L

Features:Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity.

Application:

3D Printing

MIM (Metal Injection Molding)

Spraying Welding

PM(Powder Metallurgy)

HIP(Hot Isostatic Pressing)

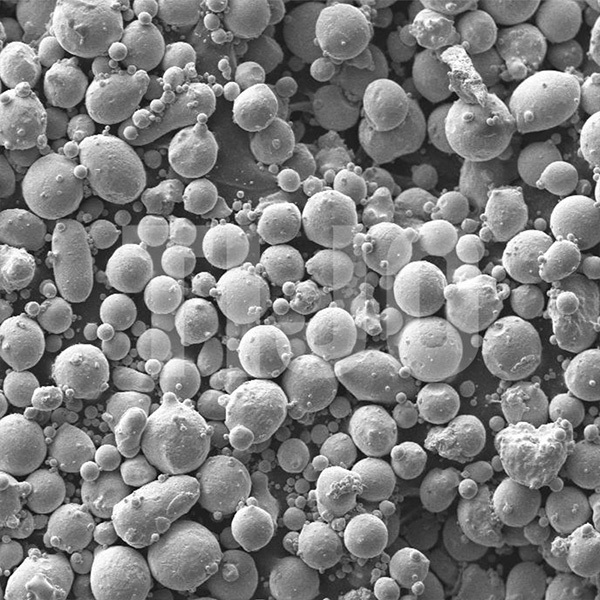

17-4PH

Features:Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity.

Application:

3D Printing

MIM (Metal Injection Molding)

HIP(Hot Isostatic Pressing)

PM(Powder Metallurgy)

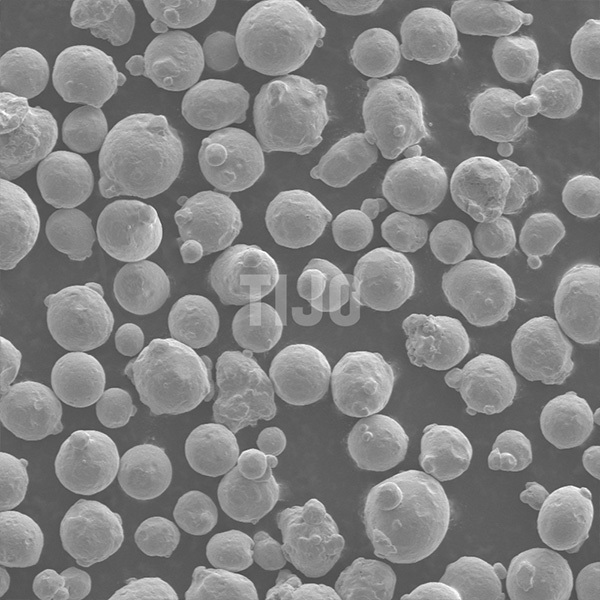

H13

Features:Gas atomization process, spherical powder, low oxygen content, uniform particle distribution, ultra fine, high density, good flowability;

Application:

3D Printing

MIM (Metal Injection Molding)

Spray Coating & Welding

HIP(Hot Isostatic Pressing)

PM(Powder Metallurgy)

M2

Features:Molybdenum series mould steel , common term is HSS, high-speed steel, and 6542, has the advantages of unevenness carbide is low and high toughness. It has high hardness, wear resistance and thermal hardness (also called red hardness)

Application:

It is used to manufacture various cutting tools with high cutting speed

It can also be used to manufacture hot & cold def

Powder Product Test Report

316L Atomization

Alloy steel powder 304L

Schematic diagram of the 17-4PH electron microscope

H13 alloy steel powder

Steel powder for molds M2

Explore material properties

Was established in 2010. Our company introduced the atomization pulverizing technology from the Powder Metallurgy Research Institute of Central South University, integrating research, development, production and sales of metal powders and alloy powders. It is a new material technology enterprise with strong research and development strength in aerosol pulverizing, with an annual capacity more than 10000 tons.

Our Advantages - Why Choose Us?

Operations Management:

1. Strictly according to ISO9001 quality management and ISO14001 environmental management system to carry out internal management, to ensure safe and pollution-free production, and constantly improve product quality;

2. Own factories, stable supply, large volume discount;

3. Reach strategic cooperation with many strength manufacturers, complete goods, to create a one-stop service;

4. Provide technical support by professional staff, grow and progress together with customers;

5. Self-constructed powder testing laboratory, can test the metal composition, oxygen, nitrogen, carbon, sulfur, powder laser particle size, powder sieve size, powder bulk density, vibration density, powder flow and other indicators to ensure that the shipment of products of 100% qualification;

6. We have a certain amount of safety stock for regular products to improve the delivery speed and customer satisfaction.

Sales Services:

1. Provide customers with 100% fully guaranteed quality services, powder quality has any problem unconditional return;

2. Provide technical guidance in some application areas to help customers improve the use of efficiency;

3. Provide customer-satisfied solutions to any powder quality problems within 24 hours.

Customer FAQs

All of our products have passed the ISO system certification, if necessary, we can provide third-party testing reports

Any questions, a salesperson will get back to you within 12 hours

What metal powder products and specifications does TIJO have?

Can TIJO be customized?

Is there a MOQ requirement for TIJO products?

Is TIJO a manufacturer or a trader?

TIJO's management team has been engaged in the metal powder material business for more than 20 years and has many quality partners in the industry. Providing customers with first-class quality products and services is our eternal pursuit.

How does TIJO ensure the quality of metal powder materials?

Our company cooperates with Powder Metallurgy Research Institute of Central South University and other domestic authoritative testing organizations (SGS, etc.) for a long time to test some special performance indexes.

Can TIJO provide free samples?