About Us

A new material enterprise focusing on new product development, large-scale production, metal powders sales and application terminal support of gas atomization powder manufacturing process technology.

PM Powder Metallurgy Technology, Processes and Applications

Changsha Tianjiu Metal Materials ProvidedPMA Complete Analysis of Powder Metallurgy Technology, Covering Processes and Applications in Automotive/Aerospace/Electronics fields, recommending iron-based/Copper-based/Stainless steel metal powders. Professional customized solutions,ISOCertification, trusted globally.

Efficient, precise, and sustainable metal component manufacturing solutions

What isPMPowder Metallurgy Technology?

Definition:Powder Metallurgy (Powder Metallurgy, PM) is a highly efficient manufacturing process that uses metal powder pressing and sintering to produce complex shapes and high-performance metal parts.

Core Advantages:

-Material utilization rate as high as97%,reducing waste

-Precise forming, reducing subsequent processing costs

-Supports multi-material composites (such as iron-based+Copper-based)

-Suitable for mass production

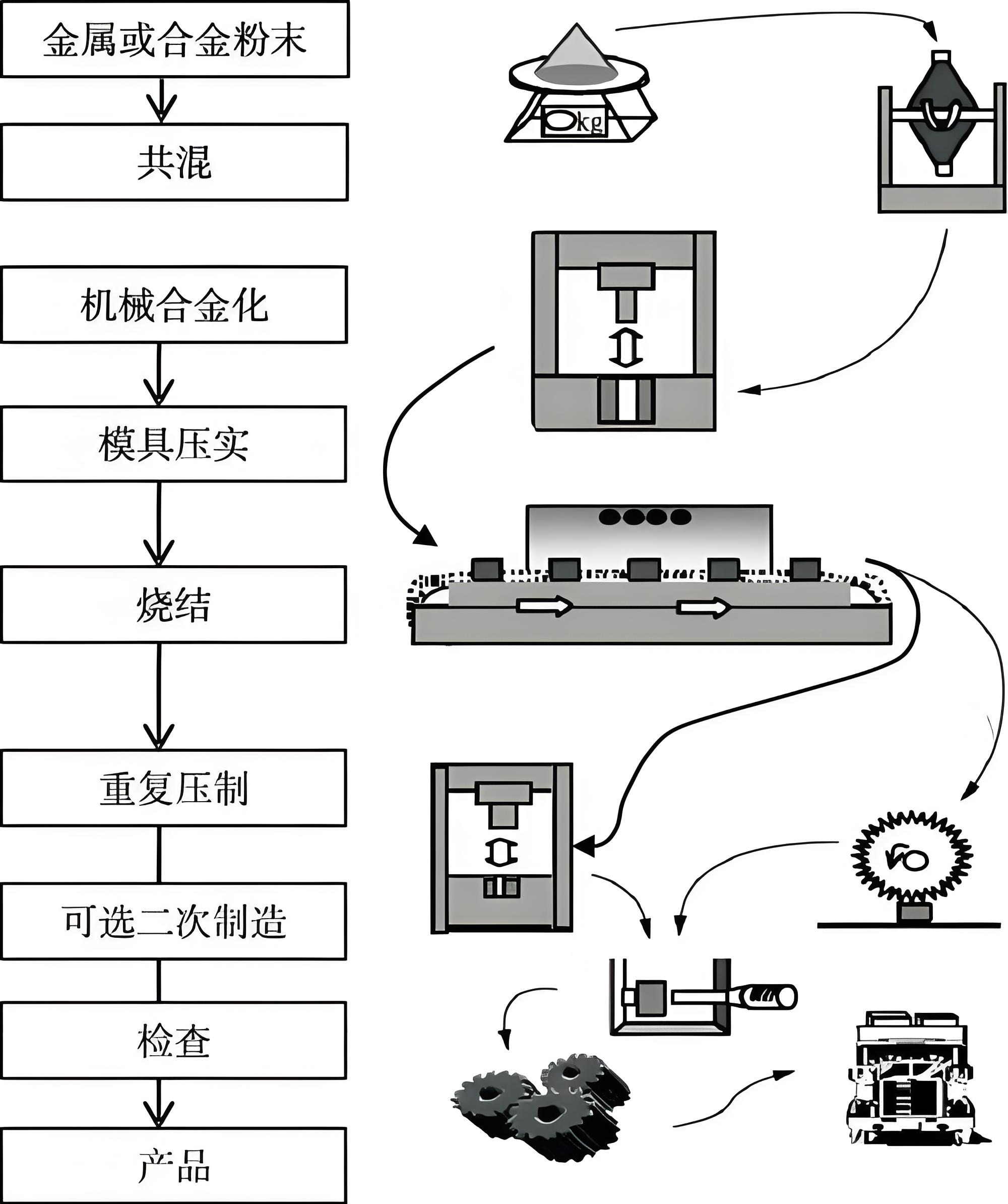

PMPowder Metallurgy Process Flow:4Four Core Steps

1.Raw Material Preparation:Select high-purity metal powders (iron, copper, stainless steel, etc.) → Mix lubricants/Alloying elements.

2.Pressing and Forming:Using mechanical/Hydraulic press (500-1000 MPa) to form "green compacts".

3.Sintering Treatment:High-temperature furnace (1100-1300°C) diffusion bonding to increase strength.

4.Post-processing:Finishing, oiling, heat treatment (optional).

PMPowder Metallurgy Applications:

Industry Solutions

1.Automotive Manufacturing

-Applied Components:Gears, connecting rods, bearing housings

-Advantages:Lightweight, wear-resistant

2.Aerospace

-Applied Components:Turbine blades, high-temperature alloy parts

3.Electronics and Electrical Appliances

-Applied Components:Heat sinks, electrical contacts (copper-based powder)

4.Medical Devices

-Applied Components:Surgical instruments, stainless steel implants

Recommended Metal Powder Products

Tianjiu Metal Powder Series |

|||

Powder Type |

Typical Grade |

Features |

Applicable Scenarios |

Iron-based Powder |

Fe-Cu-C,Fe-Ni-Mo |

High strength, low cost |

Automotive structural parts, gears |

Copper-based Powder |

Cu-Sn,Cu-Zn |

Excellent electrical and thermal conductivity |

Electronic components, heat sinks |

Stainless Steel Powder |

316L, 304L |

Corrosion resistance, biocompatibility |

Medical devices, food machinery |

Special Alloys |

WC-Co, Ti6Al4V |

Ultra-high strength, high-temperature resistance |

Aerospace, cutting tools |

Why Choose Tianjiu Metal?

-Technical Advantages:Independent research and development of ultrafine powder preparation technology (particle size can be customized to10μm)

-Quality Control'ISO 9001'Certification, full process batch tracking

-Service Support:Free powder selection scheme+ 24Hour technical response

Frequently Asked Questions (FAQ)

Q: PMWhat are the advantages of this process compared to traditional casting?

A:Higher precision (±0.1mm), less material waste, suitable for complex shapes.

Q:How can the density of stainless steel powder metallurgy parts be improved?

A:It is recommended to use double pressing+high-temperature sintering process (Tianjiu provides customized solutions).

*The above images are from Baidu. Please Contact Us if there is any infringement.

Recommend products

Maybe you want to know something else.

Contact Us

Address: No.39, Liandong Yougu lnd. Park, Bachelor Street,Changsha City,Hunan Province, China.