Good compatibility, excellent corrosion resistance of brazed joints, aesthetically pleasing process, and capable of achieving connections for complex structural components.

1. Excellent ductility in the annealed state 2. Excellent weldability 3. High fatigue strength 4. Good corrosion resistance 5. Excellent printability and surface finish 6. Good thermal and electrical conductivity, non-magnetic, low-temperature resistant 7. Non-magnetic

1. Excellent fluidity and processability in additive manufacturing systems 2. High strength-to-weight ratio, suitable for lightweight component production 3. Good thermal conductivity, low coefficient of thermal expansion 3. Good mechanical properties, including high stiffness and wear resistance 4. Cost-effective production due to reduced material waste and shorter lead times 5. Flexible creation of complex geometries and internal structures

1. Excellent weldability and castability 2. Good wear resistance 3. High corrosion resistance 4. High specific strength 5. Low coefficient of thermal expansion

1. Excellent formability: High sphericity (sphericity ≥90%), good flowability, suitable for additive manufacturing processes such as SLM (Selective Laser Melting) 2. Balanced comprehensive performance: Moderate strength (tensile strength ≥290 MPa), combined with corrosion resistance and machinability, can be heat-treated for strengthening (T6 state) 3. High purity and low oxygen content: Oxygen content ≤0.15%, pure powder, reducing printing defects and improving the density of finished products 4. Wide application adaptability: Supports multiple post-processing processes (such as anodizing, welding), and is adaptable to automobiles, aerospace, industrial molds, and other scenarios

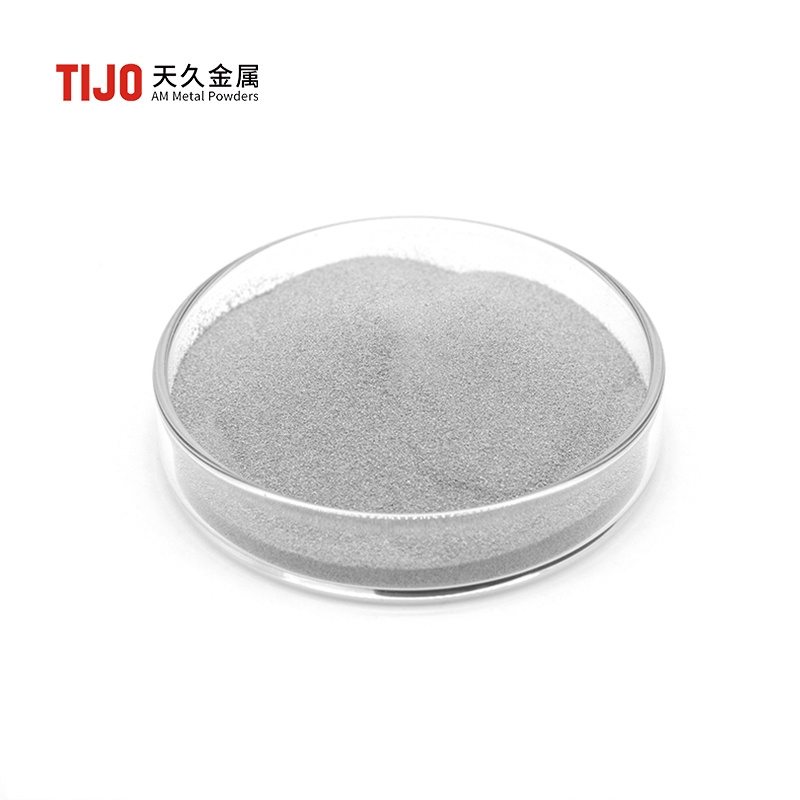

Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity

Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity

Gas atomization process, spherical powder, low oxygen content, uniform particle size, super fine powder, high density, good liquidity

Gas atomization process, spherical powder, low oxygen content, uniform particle distribution, ultra-fine powder, low density, good flowability

1.Lightweight and high-strength: Low density (approximately 2.68 g/cm³), balanced strength and toughness. 2.Heat-resistant and fatigue-resistant: Maintains good mechanical properties at high temperatures, suitable for heat dissipation structural components. 3.Excellent formability: High sphericity powder, good fluidity, printed part density ≥99%. 4.Simple post-processing: Supports secondary processing such as heat treatment, machining and surface polishing. 5.Environmentally friendly and safe: Complies with industrial environmental protection standards and releases no toxic substances.