High-quality raw material supplier for the spraying industry

As a leading domestic supplier of metal powders, Tianjiu focuses on providing high-quality metal powder raw materials for the thermal spraying industry. Through advanced powder production processes and a strict quality control system, we ensure that each batch of powder has excellent fluidity, particle size distribution, and chemical composition, providing a reliable material basis for the spraying process.

Overview of Spraying Technology

Spraying technology is a surface engineering technology that uses a heat source to heat metal or non-metal materials to a molten or semi-molten state and then sprays them at high speed onto the surface of a substrate to form a coating. This technology is widely used in aerospace, automotive manufacturing, energy equipment, electronics and electrical appliances, and other fields, and can significantly improve the wear resistance, corrosion resistance, and high-temperature resistance of workpieces.

Classification and Characteristics of Mainstream Spraying Technologies

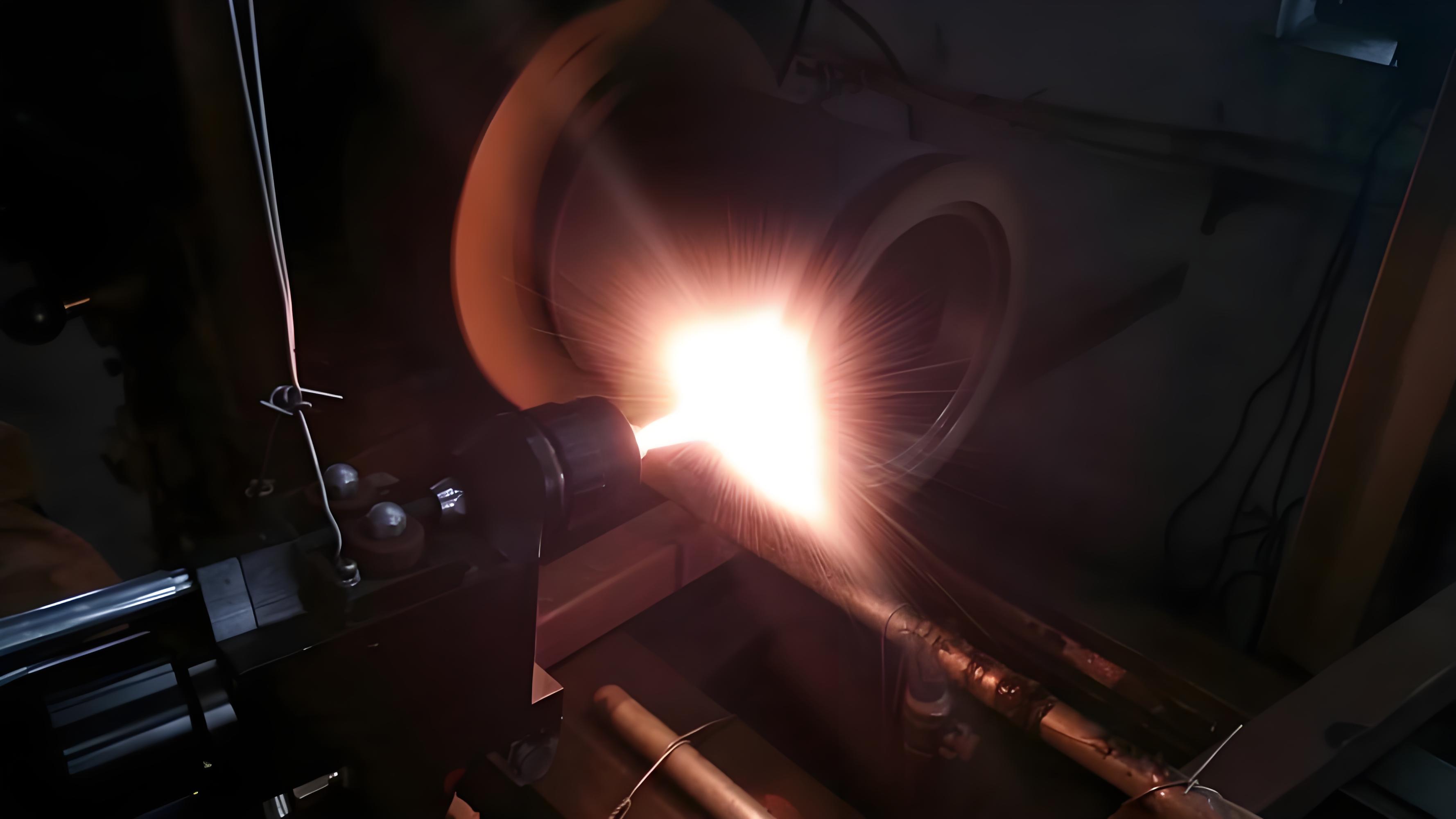

1.Plasma Spraying (APS)

Working principle: Uses a plasma arc to heat the powder to a molten state and high-speed spray it onto the substrate surface to form a coating.

Temperature range: Plasma arc temperature can reach17000℃, suitable for high melting point materials.

Coating characteristics:

-Low porosity (1-3%)

-High bonding strength (30-50MPa)

-Suitable for preparing ceramic and cermet coatings

Typical applications:

-Aerospace: Thermal barrier coatings for turbine blades

-Medical field: Hydroxyapatite coatings for artificial joints

-Electronics industry: Insulating coatings for semiconductor devices

2.High-Velocity Oxy-Fuel Spraying (HVOF)

Working principle: Uses combustion gas to generate a supersonic flame, accelerating the powder to800-1200m/sand spraying it onto the substrate surface.

Temperature range: Flame temperature is approximately3000℃, suitable for cemented carbides such as tungsten carbide.

Coating characteristics:

-Extremely low porosity (<0.5%)

-High bonding strength (>70MPa)

-High hardness (Hv 1200-1400)

Typical applications:

-Petrochemical industry: Wear-resistant coatings for valves and pump bodies

-Automotive manufacturing: Engine piston rings, gear strengthening

-Energy field: Erosion-resistant coatings for water turbine blades

3.Arc Spraying

Working principle: Uses an electric arc to heat metal wire, using compressed air to atomize the molten metal and spray it onto the substrate surface.

Temperature range: Arc temperature is approximately6000℃, suitable for low melting point metals.

Coating characteristics:

-High deposition efficiency (>90%)

-Low cost, suitable for large-area construction

-Higher coating porosity (5-10%)

Typical applications:

-Corrosion protection of bridge steel structures

-High-temperature resistant coatings for boiler pipes

-Anti-slip coatings for ship decks

4.Cold Spraying Technology

Working principle: Uses high-pressure gas to accelerate the powder to supersonic speed, forming a coating through kinetic energy rather than thermal energy.

Temperature range: Working gas temperature <600℃, no thermal deformation of the substrate.

Coating characteristics:

-No oxidation, suitable for active metals (such as titanium and magnesium)

-Dense coating, porosity <1%

-High bonding strength (>50MPa)

Typical applications:

-Electronics and electrical appliances:5GBase station radiator coating

-Aerospace: Repair of titanium alloy components

-New energy: Conductive coatings for lithium battery current collectors

Core Advantages of Spraying Technology

1.Performance Improvement

-Wear resistance: Coating hardness can reachHRC 65and above

-Corrosion resistance: Salt spray test >2000hours

-High-temperature resistance: Maximum withstand temperature1400℃

2.Economic benefits

-Extend the service life of workpieces3-5times

-Reduce equipment maintenance costs40-60% `nbsp_tag

-Reduce downtime and improve production efficiency

3.Environmental Protection

-No harmful gas emissions

-Material utilization rate >90%

-Supports the repair of waste parts, reducing resource waste

Key material selection for spraying technology

1.Powder characteristics

-Particle size distribution:15-53μmIs the common range

-Sphericity: >90%Ensure fluidity

-Oxygen content: <800ppmGuarantee coating quality

2.Substrate matching

-The coefficient of thermal expansion is close, reducing stress cracking

-Surface pretreatment (sandblasting, cleaning) improves bonding strength

3.Process parameter optimization

-Spraying distance:100-150mm

-Powder feeding rate:30-50g/min

-Gas pressure:0.6-0.8MPa

Future trends in spraying technology

1.Intelligent: Robot automatic spraying, improving accuracy and consistency

2.Green: Development of low-energy consumption and low-emission processes

3.Composite: Application of new coating materials such as nanomaterials and amorphous alloys

*All the above pictures are from Baidu. Please Contact Us if there is any infringement.

Recommend products

1. Ultra-high purity: Silver content ≥99.95%, total impurities ≤500 ppm 2. Spherical morphology: sphericity >95%, good fluidity, suitable for screen printing, spraying and other processes 3. High conductivity/thermal conductivity: volume resistivity ≤1.6 μΩ·cm, thermal conductivity ≥420 W/(m·K) 4. Controllable particle size: standard particle size 0.1-20μm (customizable), low specific surface area, high sintering activity 5. Oxidation resistance: surface coated with anti-oxidation layer (optional), extending storage and processing stability

View Details