Silver powder

Features:

1. Ultra-high purity: Silver content ≥99.95%, total impurities ≤500 ppm 2. Spherical morphology: sphericity >95%, good fluidity, suitable for screen printing, spraying and other processes 3. High conductivity/thermal conductivity: volume resistivity ≤1.6 μΩ·cm, thermal conductivity ≥420 W/(m·K) 4. Controllable particle size: standard particle size 0.1-20μm (customizable), low specific surface area, high sintering activity 5. Oxidation resistance: surface coated with anti-oxidation layer (optional), extending storage and processing stability

Application:

Packing:

Precision grinding, intelligent manufacturing technology, integrated solutions

Aluminum foil bag, iron drum, plastic drum, woven bag, pallet, customized packaging

Date of delivery:

Precision grinding, intelligent manufacturing technology, integrated solutions

3-15 days

key word:

Product Name: Silver Powder Ag

Chemical composition(wt%)

Grade | Chemical Composition ( wt% ) | ||||||||||

≮ | ≯ ( ppm ) | ||||||||||

Silver powder | Ag | Cu | Pb | Fe | Sb | Se | Te | Bi | Pd | Total impurities | |

99.99 | 25 | 10 | 10 | 10 | 5 | 8 | 8 | 10 | 100 | ||

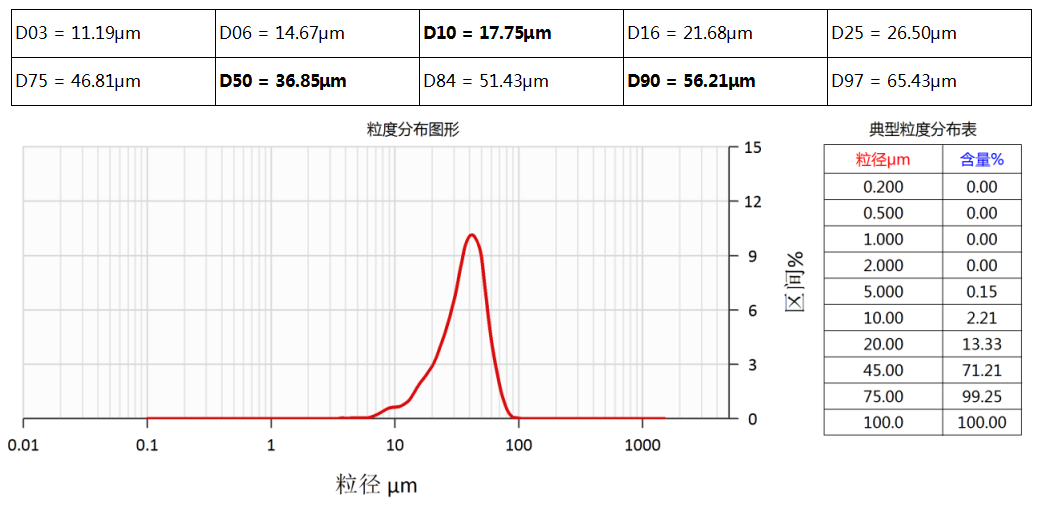

Physical indicators

CAS Registry Number: 7440-22-4

Density: 10.49 g/cm3

Melting point: 961.93 ℃

Boiling point: 2193 ℃

Specifications: -300 mesh, 15-53 μm, -100+300 mesh

Application areas

Electronics Industry

Photosensitive Material

Good optical properties, can be used to make mirrors, optical devices, etc.

Medical Field

Good antibacterial properties and can be used to make medical devices, dressings, etc.

Jewelry

Excellent process performance, beautiful appearance

Solar battery

Good electrical conductivity

Recommend products

Ternary eutectic solder, low temperature, good fluidity and process performance, will form brittle intermetallic compounds at the weld, cannot be used to connect ferrous metals, nickel-based alloys or nickel-copper alloys containing more than 10% nickel

View DetailsExcellent process performance, moderate melting point, good wetting performance and gap filling performance, excellent strength, plasticity, conductivity, corrosion resistance and other properties

View DetailsGas atomization process, spherical powder, low oxygen content, particle size controllable, low density

View Details1. Active Brazing: Titanium element breaks the oxide film, achieving high-strength metallurgical bonding between ceramic and metal. 2. High Heat Resistance: The brazing seam can withstand temperatures above 600°C, with excellent thermal shock resistance. 3. Morphological Adaptability: Powder form: ultra-fine particle size, high purity, suitable for precision preset processes. Paste form: contains low-volatility organic carriers, uniform coating, suitable for welding complex structures. 4. Strong Wettability: Excellent wettability to alumina, aluminum nitride ceramics, and refractory metals.

View Details