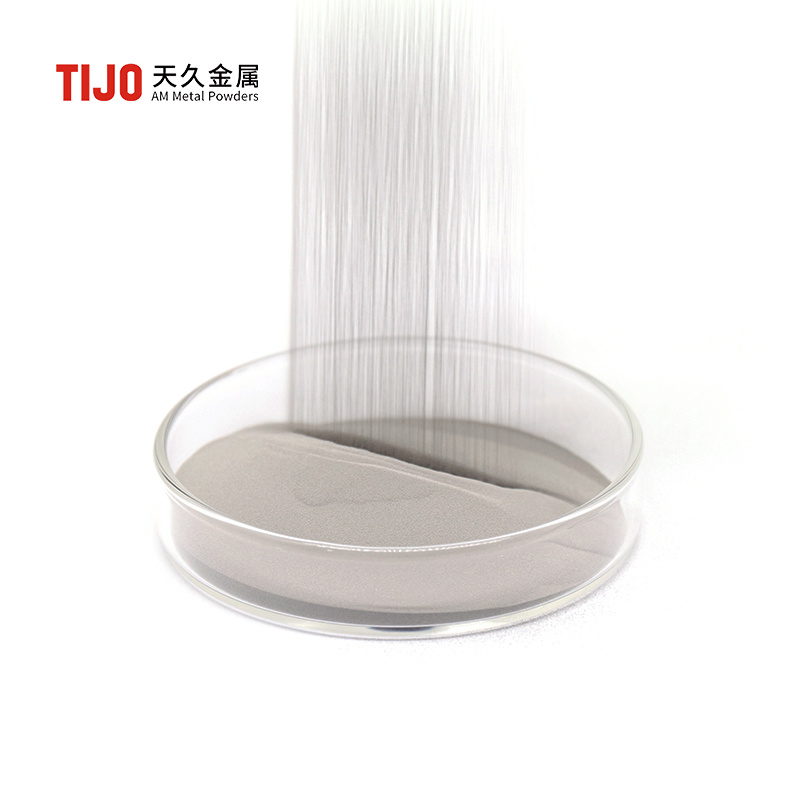

Laser cladding metal powder

Laser Cladding Technology: Principles and Advantages

Laser Cladding (Laser Cladding) is an advanced surface modification technology that uses a high-energy laser beam to simultaneously melt metal powder and the substrate, rapidly solidifying to form a dense, high-performance cladding layer.

Process Characteristics

1.High-precision bonding: The laser energy is concentrated, the heat affected zone is small, and it can achieve0.1-2mmprecise cladding of thickness.

2.Strong bonding force: The cladding layer and the substrate are metallurgically bonded, with a bonding strength of400MPaor more, and porosity <0.5%。

3.Wide applicability: Supports surface repair and strengthening of various substrates such as steel, titanium alloys, and nickel-based superalloys.

4.Environmentally friendly and efficient: Material utilization rate exceeds95%reducing pollution problems of traditional electroplating/and thermal spraying.

Core Applications

-Industrial repair: Repairing worn/and corroded parts such as gears, shafts, and molds, reducing costs by30%-50%。

-Additive manufacturing: Used for direct forming of complex components in aerospace (DEDprocess).

-Surface strengthening: Improving the wear and corrosion resistance of parts such as oil drills and hydraulic rods.

Recommended Metal Powders for Laser Cladding

Changsha Tianjiu provides the following high-performance metal powders to meet different process needs:

1.Nickel-based alloy powder

-Typical grade:inconel625(NiCrMo),inconel718(NiCrFeNb)

-Component characteristics: High temperature resistance (1200℃+), corrosion resistance, chromium element for oxidation resistance.

-Application scenarios: Repair of gas turbine blades, additive manufacturing of aero-engine components.

-Technical parameters: sphericity >98%,oxygen content <0.08%,flowability ≤15s/50g。

2.Cobalt-based alloy powder

-Typical grade:Co6(CoCrW),Co12(CoCrMo)

-Component characteristics: High hardness (HRC 55-65), wear resistance, suitable for extreme friction environments.

-Application scenarios: Valve sealing surfaces, oil drill cladding, mining machinery strengthening.

3.Iron-based alloy powder

-Typical grade:316L(stainless steel),FeCr(high chromium cast iron)

-Component characteristics: Low cost, strong fatigue resistance, adjustable hardness rangeHRC 30-60。

-Application scenarios: Food machinery repair, surface strengthening of agricultural machinery parts, mold repair.

4.Composite powder

-Typical grade:WC/Co(tungsten carbide cobalt),AlSi(aluminum silicon alloy)

-Component characteristics:WCparticles enhance wear resistance,AlSialloys improve heat conduction and lightweighting.

-Application scenarios: Tool edge cladding, automotive lightweighting component manufacturing.

Three Reasons to Choose Tianjiu Metal Powders

1.Strict quality control: Complies withISO 9001andAMS 4999Astandards, mass production consistency reaches99.5%。

2.Customized service: Supports powder composition, particle size (10-150μm), oxygen content (can be controlled <0.05%) customization.

3.Global supply: Provides sea freight/and air freight standardized packaging, and conventional products7days fast delivery.

*Some of the above pictures are from Baidu. Please contact us if there is any infringement.

Recommend products

1. Excellent Corrosion Resistance: High molybdenum (Mo) content enhances resistance to pitting and crevice corrosion, suitable for harsh environments such as marine and chemical applications. 2. Biocompatibility: Certified for biocompatibility according to ISO 10993, suitable for manufacturing medical devices and implants. 3. High Purity and Low Impurities: Oxygen content ≤0.1%, carbon content ≤0.03%, reducing printing defects and ensuring the density and strength of finished products. 4. Excellent Processing Performance: High sphericity (≥95%), good fluidity (Hall flow rate ≤25 s/50g), suitable for additive manufacturing processes such as SLM and EBM.

View Details1. High-Temperature and Corrosion Resistance Temperature range: -200°C to 1000°C, oxidation and sulfidation corrosion resistance. Resistant to seawater, chlorides, and acidic media corrosion, suitable for marine and chemical environments. 2. Excellent Processability High sphericity (≥98%), low oxygen content (≤0.1%), good fluidity, reducing 3D printing defects. Strong bonding strength with the substrate, supporting the formation of high-precision complex structures. 3. High Strength and Toughness Room temperature tensile strength ≥900 MPa, maintaining excellent mechanical properties at high temperatures.

View Details1. High-Temperature Performance Applicable temperature range: -250°C to 700°C, resistant to high-temperature oxidation, creep, and sulfide corrosion. Strength is significantly improved after age hardening (room temperature tensile strength ≥ 1300 MPa). 2. Corrosion Resistance Resistant to acids, alkalis, chlorides, and seawater corrosion, suitable for chemical, marine, and nuclear industries. 3. Process Compatibility High sphericity (≥97%), low oxygen content (≤0.1%), excellent fluidity, compatible with additive manufacturing processes such as SLM (Selective Laser Melting) and EBM (Electron Beam Melting). No tendency for cracking after welding, supports the precision forming of complex structures.

View Details1. High-temperature oxidation resistance: Excellent oxidation resistance below 800℃, suitable for high-temperature environment components. 2. Cost-effective: Nickel-free design reduces costs and offers excellent value. 3. Magnetic properties: Exhibits ferromagnetism, suitable for electromagnetic devices and shielding materials. 4. Easy forming: High fluidity powder, suitable for pressing, sintering and 3D printing processes. 5. Environmental protection: Compliant with RoHS standards and recyclable.

View Details