Inconel625

Features:

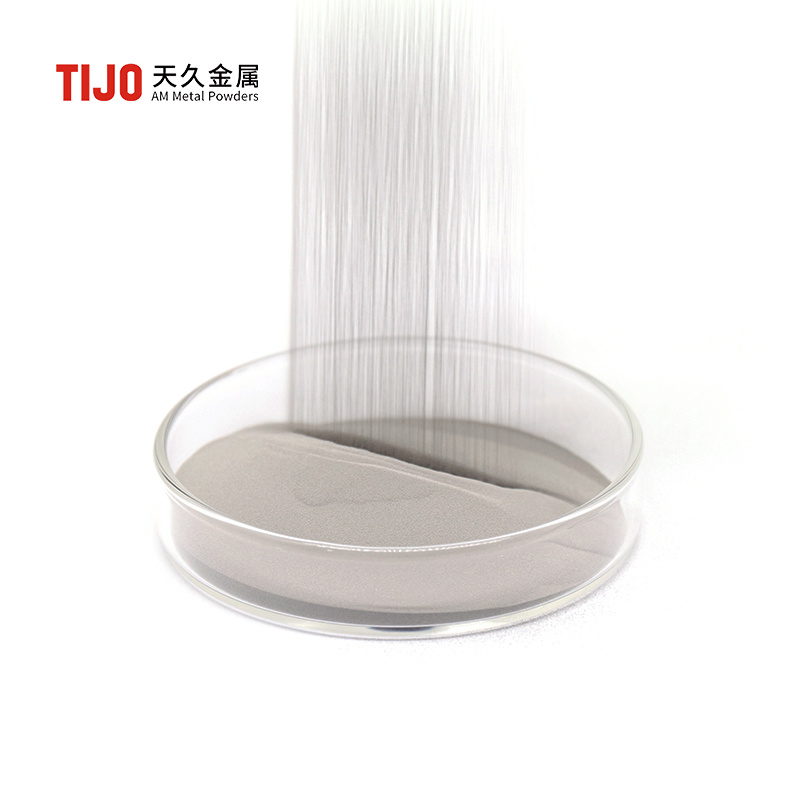

1. High-Temperature and Corrosion Resistance Temperature range: -200°C to 1000°C, oxidation and sulfidation corrosion resistance. Resistant to seawater, chlorides, and acidic media corrosion, suitable for marine and chemical environments. 2. Excellent Processability High sphericity (≥98%), low oxygen content (≤0.1%), good fluidity, reducing 3D printing defects. Strong bonding strength with the substrate, supporting the formation of high-precision complex structures. 3. High Strength and Toughness Room temperature tensile strength ≥900 MPa, maintaining excellent mechanical properties at high temperatures.

Application:

MIM (Metal Injection Molding)

PM (Powder Metallurgy)

HIP (Hot Isostatic Pressing)

Packing:

Precision grinding, intelligent manufacturing technology, integrated solutions

Aluminum foil bag, iron drum, plastic drum, woven bag, pallet, customized packaging

Date of delivery:

Precision grinding, intelligent manufacturing technology, integrated solutions

3-15 days

key word:

Model: Inconel625(GH3625) high-temperature alloy powder

-GH3625、GH625、0Cr22Ni60Mo9Nb4(National Standard)

- NiCr22Mo9Nb(ISO)

- NO6625、Inconel625(UNS、ASTM(USA)

- NC22DNb(NF(France)

- W.Nr.2.4856(DIN(Germany)

- NA 21(BS(UK)

- NS336、NS3306(Corrosion-resistant name)

- alloy625

【Common Specification (mesh)Specifications(mesh)】15-53μm、45-150μm

Chemical composition(wt%)

Plate Number | Chemical Composition (wt%) | |||||||||||||

Other≯ | ||||||||||||||

Inconel625 | Cr | Mo | Nb | Fe | C | Co | Al | Ti | Si | Mn | Cu | P | S | Ni |

20.0-23.0 | 8.0-10.0 | 3.15-4.15 | 5.0 | 0.1 | 1.0 | 0.4 | 0.4 | 0.5 | 0.5 | 0.07 | 0.015 | 0.015 | Bal. | |

Physical indicators

Powder Specification | Bulk Density (g/cm³) | Hall Flow Rate (s/50g) | Oxygen Content (ppm) | Particle Size Distribution (μm) | ||

D10 | D50 | D90 | ||||

53-150μm | 4.5-4.8 | ≤25 | 300-500 | 56-66 | 90-102 | 135-155 |

15-45μm | 4.4-4.8 | ≤25 | 300-500 | 16-20 | 27-32 | 47-51 |

15-53μm | 4.4-4.9 | ≤25 | 300-500 | 17-22 | 30-34 | 48-55 |

20-60μm | 4.3-4.9 | ≤25 | 300-500 | 20-25 | 32-37 | 51-61 |

Application areas

Aerospace

Nuclear Industry

Used to make cladding tubes, support frames, cooling tubes and other key components. In nuclear fuel components and nuclear reactor structural components

Petroleum and natural gas industries

Excellent corrosion resistance and tensile strength ideal for manufacturing valves, pipes, and other equipment working in high pressure and high temperature environments

Ocean Field

It has good corrosion resision and can be used in various environments including seawater, fresh water and seawater

Recommend products

1. High-Temperature Performance Applicable temperature range: -250°C to 700°C, resistant to high-temperature oxidation, creep, and sulfide corrosion. Strength is significantly improved after age hardening (room temperature tensile strength ≥ 1300 MPa). 2. Corrosion Resistance Resistant to acids, alkalis, chlorides, and seawater corrosion, suitable for chemical, marine, and nuclear industries. 3. Process Compatibility High sphericity (≥97%), low oxygen content (≤0.1%), excellent fluidity, compatible with additive manufacturing processes such as SLM (Selective Laser Melting) and EBM (Electron Beam Melting). No tendency for cracking after welding, supports the precision forming of complex structures.

View DetailsBNi-2 is one of the most widely used nickel-based brazing alloys, characterized by a low melting temperature, good wettability, and fluidity. During the brazing process, the base material grains do not grow, which helps prevent deterioration of component performance.

View DetailsThe carbon and boron in BNi-1 brazing filler metal can diffuse into the base material during the brazing process, thereby increasing the remelting temperature of the brazed joint. This filler metal has a high chromium content, so the brazed joint exhibits good high-temperature performance and is suitable for components subjected to high stress at elevated temperatures.

View DetailsBNi-5 brazing filler metal does not contain boron, significantly reducing its effect compared to the base material. It is suitable for brazing thin parts. This filler metal has a high melting temperature and brazing temperature. Due to its high chromium content, the joint's high-temperature strength and oxidation resistance are comparable to BNi-1.

View Details