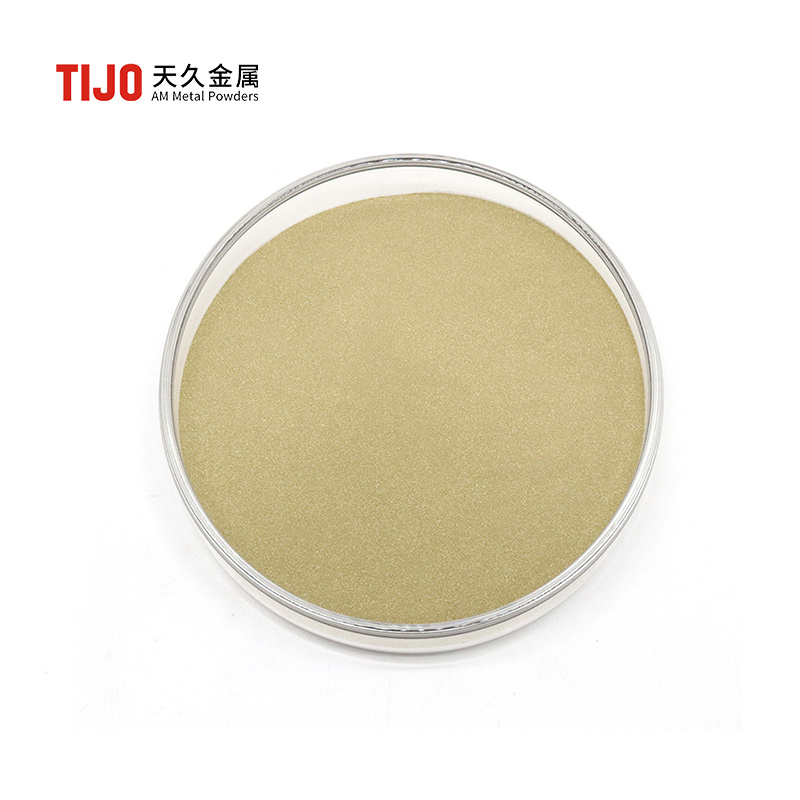

Silver-clad copper powder

Features:

1. High Electrical and Thermal Conductivity: The surface silver layer provides silver-like conductivity (resistivity ≤2.5 × 10⁻⁶ Ω·m) 2. Strong Oxidation Resistance: The silver layer isolates the copper substrate from oxidation, extending the material's stability 3. Cost Advantage: Significantly reduces the amount of precious metals used, with a higher price-performance ratio than pure silver powder 4. Process Adaptability: Compatible with various processing methods such as cold pressing and sintering, spraying, and paste printing

Application:

Used for preparing conductive printing inks

Used for preparing conductive adhesives

Used for preparing medium and low temperature pastes for membrane switches, can replace silver powder in the electronics industr

Packing:

Aluminum foil bag, iron drum, plastic drum, woven bag, pallet, customized packaging

Date of delivery:

Precision grinding, intelligent manufacturing technology, integrated solutions

3-15 days

key word:

Product Name: Silver Bag Copper Powder

Chemical composition(wt%)

|

Composition ComponentsComposition(wt%) |

||||||||

|

No. |

Specification |

Ag(wt%) |

Cu(wt%) |

BET(m²/g) |

D10(μm) |

D50(μm) |

D90(μm) |

|

|

1 |

CuAg-S0501 |

15-30 |

Bal. |

1.50-2.50 |

≤1.00 |

≤2.00 |

≤4.00 |

|

|

2 |

CuAg-S1001 |

10-30 |

Bal. |

0.45-0.65 |

≤2.50 |

≤4.00 |

≤5.50 |

|

|

3 |

CuAg-S3501 |

10-30 |

Bal. |

0.25-0.45 |

≤3.80 |

≤6.00 |

≤9.30 |

|

|

4 |

CuAg-F0501 |

15-30 |

Bal. |

1.90-2.00 |

≤1.70 |

≤3.70 |

≤5.60 |

|

|

5 |

CuAg-F1001 |

10-30 |

Bal. |

0.80-0.95 |

≤3.20 |

≤4.80 |

≤6.30 |

|

|

6 |

CuAg-F3501 |

20-30 |

Bal. |

0.55-0.75 |

≤3.50 |

≤5.80 |

≤7.50 |

|

Physical indicators

Application areas

Conductive paste

Conductive printing ink

Conductive adhesive

Low-temperature slurry

Substitute silver powder

Recommend products

Ternary eutectic solder, low temperature, good fluidity and process performance, will form brittle intermetallic compounds at the weld, cannot be used to connect ferrous metals, nickel-based alloys or nickel-copper alloys containing more than 10% nickel

View DetailsGas atomization process, spherical powder, low oxygen content, particle size controllable, low density

View DetailsExcellent process performance, moderate melting point, good wetting performance and gap filling performance, excellent strength, plasticity, conductivity, corrosion resistance and other properties

View Details