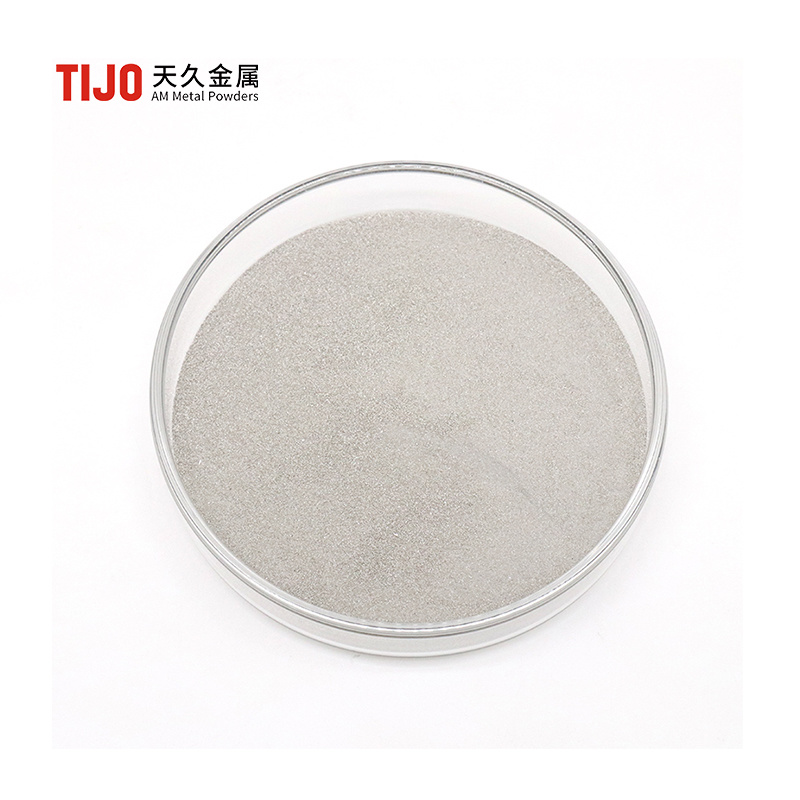

SnAgCu0307

Features:

It has low melting point, good wettability and fatigue resistance, and the volume of the solder expands slightly when it solidifies which is beneficial to eliminating shrinkage cavities; its low melting point can meet the needs of packaging of electronic

Application:

Packing:

Precision grinding, intelligent manufacturing technology, integrated solutions

Aluminum foil bag, iron drum, plastic drum, woven bag, pallet, customized packaging

Date of delivery:

Precision grinding, intelligent manufacturing technology, integrated solutions

3-15 days

key word:

Model:SnAgCu0307

Chemical composition(wt%)

|

Code |

Chemical Composition(wt%) |

||||||||

|

|

Sn |

Ag |

Cu |

Impurities, ≤ |

|||||

|

|

|

|

|

Pb |

Sb |

Bi |

Zn |

Al |

As |

|

SnAgCu0307 |

98.5-99.5 |

0.2-0.4 |

0.5-0.9 |

0.050 |

0.050 |

0.050 |

0.001 |

0.001 |

0.030 |

|

|

|

|

|

Au |

Cd |

Fe |

Ge |

Ni |

In |

|

|

|

|

|

0.050 |

0.002 |

0.020 |

0.050 |

0.010 |

0.050 |

Physical indicators

【Density】7.3g/cm3

【solidus】227℃

【Specifications】25-45μm、15-25μm、5-20μm

Application areas

Aerospace

High temperature resistance and corrosion resistance and can be used as turbine blade material for engines

Electronics Industry

Used for welding in the manufacture of various electronic components, circuit boards, mobile phones, laptops and other electronic products.

Recommend products

Centrifugal atomization process, low melting point, high purity, high sphericity rate, uniform particle size distribution, quality stable

View Details